Georgia

Rwataw Highway

Construction is one of the spheres of human life, where new technologies and materials find their application especially quickly. Without pretending to be objective, we have collected in one article several products, as well as buildings under construction or under construction, which seemed to us worthy of attention more than others.

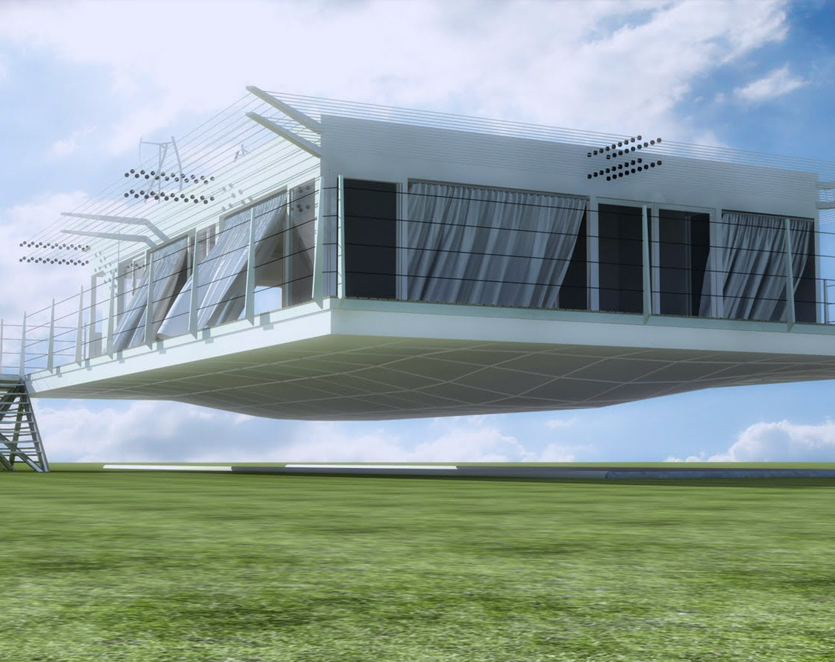

Okay, albeit not soaring, but capable of lifting a few centimeters above the ground in the event of an earthquake and staying in this position until the end of the tremors.

As you might guess, this technology was developed in Japan, moreover, in the last decade - however, they paid attention to it in the Land of the Rising Sun only after the devastating earthquake of 2011.

The system, developed by the designers of Air Danshin Systems Inc., assumes the presence of a powerful air cushion that allows the house to hover above the ground for the right time if necessary. The sensitive sensor is capable of detecting the onset of seismic activity in advance. It gives a signal to activate the air compressor. The latter takes a few seconds to fill with air a special pillow between the house itself and its foundation. The thickness of such a pillow is only a few centimeters, but this is quite enough to significantly reduce damage from an earthquake. After the end of the aftershocks, the house sits on a special frame around the perimeter of the foundation. About a hundred houses have already been built in Japan using the new technology. Some of them are not very large buildings, destroyed by an earthquake seven years ago and then rebuilt according to new technology, without a rigid connection to the foundation.

The idea of "flying houses" has already attracted interest in other Asian countries, also like Japan, located in areas with increased seismic activity.

Its creators borrowed the idea of a new product, as is often the case, from nature. Namely - in a seashell containing a complex of minerals that affect its growth. Scientists at the University of Michigan, Victor Li and Yingzi Yang, set out to create concrete that can independently "heal" cracks formed, for example, as a result of an earthquake.

After they finally decided on the composition for the concrete mix, the new product showed truly amazing properties. Having covered itself with a network of cracks due to a tensile load of 5%, it not only held them together, but also restored its original shape. Ordinary concrete in such tests would simply break into pieces.

Water helps to restore its shape and quality to innovative concrete. Interacting with it for several days, it reacts with mineral additives and other compounds contained in concrete, as well as with carbon dioxide from the atmosphere - and the scars on the concrete slab are healed with calcium carbonate. At the same time, the plate restored in this way will practically not lose anything in strength.

US innovators see their concrete as being used in construction, including road construction, and especially in bridge construction. They remind that an earlier version of resilient concrete has already been used to build a bridge in their home state: the roadway is completely jointless, and cars pass through it almost silently. A product similar in its properties was used in the construction of a sixty-story skyscraper in the Japanese city of Osaka.

The University of British Columbia dormitory was the tallest wooden building in the world when it moved in last September. It was built of cross-laminated timber, which surpasses steel in strength and is very resistant to fire.

The 53-meter building, dubbed Brock Commons, was designed and built by the Canadian architecture firm Acton Ostry. As its representatives emphasize, all the wood that went to the production of timber was mined in the forests of British Columbia. The construction process, aside from the interior decoration, was completed in a record 70 days. The hostel is designed for 400 students, who currently live in it.

To be fair, it should be noted that cross-laminated timber CLT (cross-laminated timber) is not a novelty on the building materials market: it appeared on the market back in the 90s of the last century. Numerous layers of this material are glued in such a way that the fibers of the previous layer are always located perpendicular to the fibers of the next. This technology gives the material high strength, while its production is practically waste-free. An innovation is the construction of high-rise buildings from CLT and other modern wood processing products - for their designation even a special word plyscraper appeared, by analogy with the famous skyscraper, "skyscraper".

Building from salt, which in the proverbs and sayings of different peoples is synonymous with futile efforts, the Dutch architect Eric Jobers was able to turn it into reality by developing an environmentally friendly technology for the production of blocks based on sea water.

Using solar energy, salt is extracted from the ocean and then mixed with starch from seaweed. The output is brick-like blocks that have high compressive strength. Buildings constructed from such blocks are covered with an epoxy-based material, after which no moisture can damage them. Salt blocks are also quite suitable for creating flexible arched structures.

For arid countries, Eric Jobers emphasizes, this construction technology is optimal. The first small city entirely built of salt blocks will be built in Qatar.

The Celestial Empire has more than once amazed the whole world with the scale of its construction projects, be it the Great Wall or the world's longest suspension bridge. This time, in the Chinese city of Chongqing, they took up the construction of a horizontal Conservatory skyscraper, which will rely on the roofs of four 250-meter high-rise buildings. The author of the project is the architect Moshe Safdie, the contractor is the CapitaLand company. The complex of buildings will include two more high-rise buildings, the construction of which is being carried out simultaneously with the construction of a horizontal skyscraper. All seven buildings will be connected to each other by overhead passages and form a single architectural ensemble.

Inside the Conservatory there will be apartments, hotels, offices, a shopping center and a spacious recreation area with a swimming pool, gardens and observation decks. The weight of the slightly curved horizontal tower is 12 thousand tons. For its construction, 3200 glasses and 4800 aluminum panels will be required. The structure consists of nine segments, four of which will be assembled on site, one at each of the skyscrapers. The three intermediate segments will be welded to the ground and lifted into place with hydraulic jacks. Finally, the two outermost segments will be assembled from the short sections last. Installation of the structure is planned to be completed this year.

The Conservatory horizontal skyscraper, like the entire Raffles City Chongqing complex, is being erected in accordance with the green LEED Gold standard. It includes measures to reduce the absorbed heat and an efficient irrigation system, which will reduce the cost of air conditioning the building. The issues of recycling construction waste and their disposal have also been thoroughly worked out.

The engineering firm Arup, responsible for the safety of the building complex, assures that the seismic and wind resistance of the buildings will be at the highest level.